Articles

blog

3 Things to Consider When Adding a Fire Pit to your Backyard

Read post

brochures

321-508 | Paver Care Products

Download

brochures

341-430 | Efflorescence Control and Removal

Download

brochures

341-441 | iN Natural Look Paver Protector New and improved packaging

Download

brochures

341-497 | Preventive Maintenance of Paver Installations

Download

brochures

341-503 | New Cleaners & Stain Removers

Download

brochures

341-517 | Techniseal Medical-Grade Hand Sanitizer

Download

brochures

341-519 | New Techniseal Retail Packaging

Download

brochures

341-537 | Techniseal Multi-Surface Paver Protectors

Download

brochures

Brochure Homeowner CAN-EN 2024

Download

faq

FAQ - Concrete Paver Sealers

Read more

faq

FAQ - Polymeric Jointing Sand

Read more

faq

FAQ | Techniseal Wood Care Products

Read more

news

Introducing our Newly Revamped Jointing Product Calculator

Read more

photos

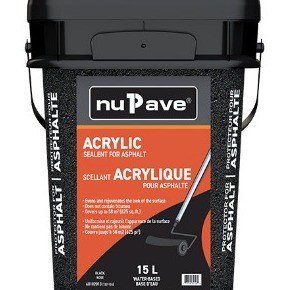

nuPave Prot. Asphalt 15L | 60102013

Download

blog

Protecting Concrete Pavers From Damages Caused by De-icing Salts

Read post

brochures

Step by Step | Asphalt Treatments | hm_en

Download

brochures

Step by Step | Carbopoxy System | hm_en

Download

brochures

Step by Step | Paver Care | hm_en

Download

brochures

Step by Step | Polymeric Sands | hm_en

Download

brochures

Step by Step | Roofing Treatments | hm_en

Download

brochures

Step by Step | Wood Treatments | hm_en

Download

Logo

Techniseal EdgeBond - Logo

Download

Logo

Techniseal HP NextGel - Logo

Download

news

Techniseal Introduces its New and Improved Paver Sealer Calculator

Read more

news

Techniseal unveils its new and improved website

Read more

photos

TSL Acc. Acry Patch Comp 6.5Kg | 70978065

Download

photos

TSL Acc. Acryl Crack Filler 1L | 70978054

Download

photos

TSL Acc. Carbochips Met 325g | 70978060

Download

photos

TSL Acc. Carbochips Saha 325g | 70978061

Download

photos

TSL Acc. Carbochips Spor 325g | 70978062

Download

photos

TSL Acc. Carbogrit 40g | 70978063

Download

photos

TSL Acc. Crack Fil Aspha 300ml | 70978056

Download

photos

TSL Acc. Crack Fil Conc. 300ml | 70978057

Download

photos

TSL Acc. Exact Sprayer | 70971143

Download

photos

TSL Acc. Inst. Leak Blac 369g | 70978079

Download

photos

TSL Acc. Inst. Leak Clr 369g | 70978078

Download

photos

TSL Acc. Inst. Leak Whit 369g | 70978077

Download

photos

TSL Acc. Oilspot Prim Asph. 1L | 70978047

Download

photos

TSL Acc. Slit Foam Roller | 70971145

Download

TSL Acc. Stain Remover Brush | 70971144

Read more

photos

TSL Acc. Surefoot Grit SB 160G | 60102015

Download

photos

TSL Acc. Thick Pile Roller | 70978075

Download

photos

TSL Acc. Waterproof Slt 300ml | 70978066

Download

photos

TSL Adh. RG+ Conc Adhes 300 ml | 70971142

Download

photos

TSL Adh. RG+ Conc Adhes 828 ml | 70975912

Download

photos

TSL Clean. Pre-Seal Cleaner 4L | 60102041

Download

photos

TSL Cln. Alu And Vinyl 1L | 60102017

Download

photos

TSL Cln. Dirt Grease Asph. 1L | 60102027

Download

photos

TSL Cln. Dirt Grease Clean 1L | 60102030

Download

photos

TSL Cln. Dirt Grease | 60102031

Download

photos

TSL Cln. Efflo Prep 4L | 60102040

Download

photos

TSL Cln. Hardscape Cleaner | 60101011

Download

photos

TSL Cln. Organic | 60102044

Download

photos

TSL Cln. Paint Stripper 4L | 60102024

Download

photos

TSL Cln. Paint/Tar Remover | 60100111

Download

photos

TSL Cln. Pro Oil Grease | 60102032

Download

photos

TSL Cln. Roof Cleaner 850g | 60102039

Download

photos

TSL Cln. Rust Remover | 60100115

Download

photos

TSL Cln. Stain Stripper 4L | 60102022

Download

photos

TSL Cln. Wood Cleaner 850g | 60102038

Download

photos

TSL EZ Sand Grey | 40100603

Download

photos

TSL EZ Sand Tan | 40100604

Download

photos

TSL Prot. Asphalt Epox HP 15L | 60102111

Download

photos

TSL Prot. Asphalt First 15L | 60701331

Download

photos

TSL Prot. Asphalt Rg 15L | 60102114

Download

photos

TSL Prot. Carbo Clear 3.78L | 60102126

Download

photos

TSL Prot. Carbo Desert 3.78L | 60102127

Download

photos

TSL Prot. Carbo Grey 3.78L | 60102128

Download

photos

TSL Prot. Carbo Karbone 3.78L | 60102129

Download

photos

TSL Prot. Carbo Titane 3.78L | 60102130

Download

photos

TSL Prot. IN 3.78L | 60102138

Download

photos

TSL Prot. Int .Sand 3.78L | 60102169

Download

photos

TSL Prot. Int. Clear 18.93L | 60102167

Download

photos

TSL Prot. Int. Clear 3.78L | 60102168

Download

photos

TSL Prot. Int. Grey 3.78L | 60102166

Download

photos

TSL Prot. Int. Grey Blue 3.78L | 60102165

Download

photos

TSL Prot. Primer Garage 3.78L | 60102115

Download

photos

TSL Prot. Surefoot WB 114Gr | 60102092

Download

photos

TSL Prot. Urethane Conc. 3.78L | 60102164

Download

photos

TSL Prot. WA 18.93L | 60300158

Download

photos

TSL Prot. WA 3.78L | 60300163

Download

photos

TSL Prot. WL1-2 18.93L | 60102172

Download

photos

TSL Prot. WL1-2 3.78L | 60102173

Download

photos

TSL Prot. Wood Cedar | 60102117 (144-353)

Download

photos

TSL Prot. Wood Chocolate| 60102118

Download

photos

TSL Prot. Wood Forest | 60102119

Download

photos

TSL Prot. Wood Honey | 60102120

Download

photos

TSL Prot. Wood Mahogany | 60102116

Download

photos

TSL Prot. Wood Natural | 60102123

Download

photos

TSL Prot. Wood Pine | 60102125

Download

photos

TSL Prot. Wood Preserv. 1L | 60102155

Download

photos

TSL Prot. Wood Preserv. 3.78L | 60102156

Download

photos

TSL Prot. Wood Walnut | 60102124

Download

photos

TSL Prot. WR7 18.93L | 60102143

Download

photos

TSL Prot. WR7 3.78L | 60102144

Download

photos

TSL Roofkeep Black 10Yrs 15L | 60102181

Download

photos

TSL Roofkeep Black 5 Yrs 15L | 60102183

Download

photos

TSL Roofkeep Brown 10Yrs 15L | 60102174

Download

photos

TSL Roofkeep Brown 5Yrs 15L | 60102187

Download

photos

TSL Roofkeep Grey 10Yrs 15L | 60102178

Download

photos

TSL Roofkeep Grey 5Yrs 15L | 60102180

Download

photos

TSL Roofkeepclear 10Yrs 15L | 60102176

Download

photos

TSL Roofskin Alum 25Yrs 15L | 60102188

Download

photos

TSL Sand RG+ Grey 50Lbs | 40105160

Download

photos

TSL Sand RG+ Tan 22.7Kg | 40100593

Download

blog

Why Choose Polymeric Sand For Paver Jointing?

Read post